maintenance streamlined high performance pigging technology for fluid transfer?

Within the sphere of manufacturing procedures, upholding the soundness and effectiveness of channels is critical. Aggregation of filth within channels can substantially block flow rates, lessen yield grade, and augments preservation fees. To deal with these challenges, pipeline cleaning processes have surfaced as preeminently adept measures for uninterrupted tube purging. A pig, essentially a tubular implement, is driven through the pipe, effectively scrubbing impurities and maintaining peak operation

Channel scrubbing processes provide plentiful assets. They are adaptable, ready to scrubbing pipelines of heterogeneous sizes and ingredients. Furthermore, they are effective, performing the activity in a relatively short timespan. By reducing downtime and enriching pipeline capacity, pipeline cleaning systems advance cost reductions and expanded operational production

Sanitation Pigging Methods:

Sustaining pipeline purity is fundamental for guaranteeing offer assurance and superiority of moved commodities. Sanitary pigging methods provide a steady way to reach this aim. Pigs, specific implements, are deployed into pipelines to sterilize by eliminating residues and filth

- Myriad models of sanitary pigs come, each created for particular cleaning jobs.

- These pigs are manufactured from matter that meet stringent sterile standards.

- Scheduled sanitary pigging exercises assist warding off product pollution, increase pipeline survival, and escalate overall productivity.

Next-Generation Pigging Approaches for Prime Performance

In the sector of channel support, high-tech pigging technologies have emerged as a key device for maintaining maximum capability and conservation. These cutting-edge systems utilize inventive designs and aspects to efficiently sterilize, check, and maintain passages from degradation. From advanced pigs outfitted with immediate analysis modules to custom pigging apparatus created for difficult tasks, improvement in this branch is persistently expanding horizons. By applying these enhancements, operators can significantly boost pipeline sturdiness, minimize downtime, and optimize operational effectiveness.

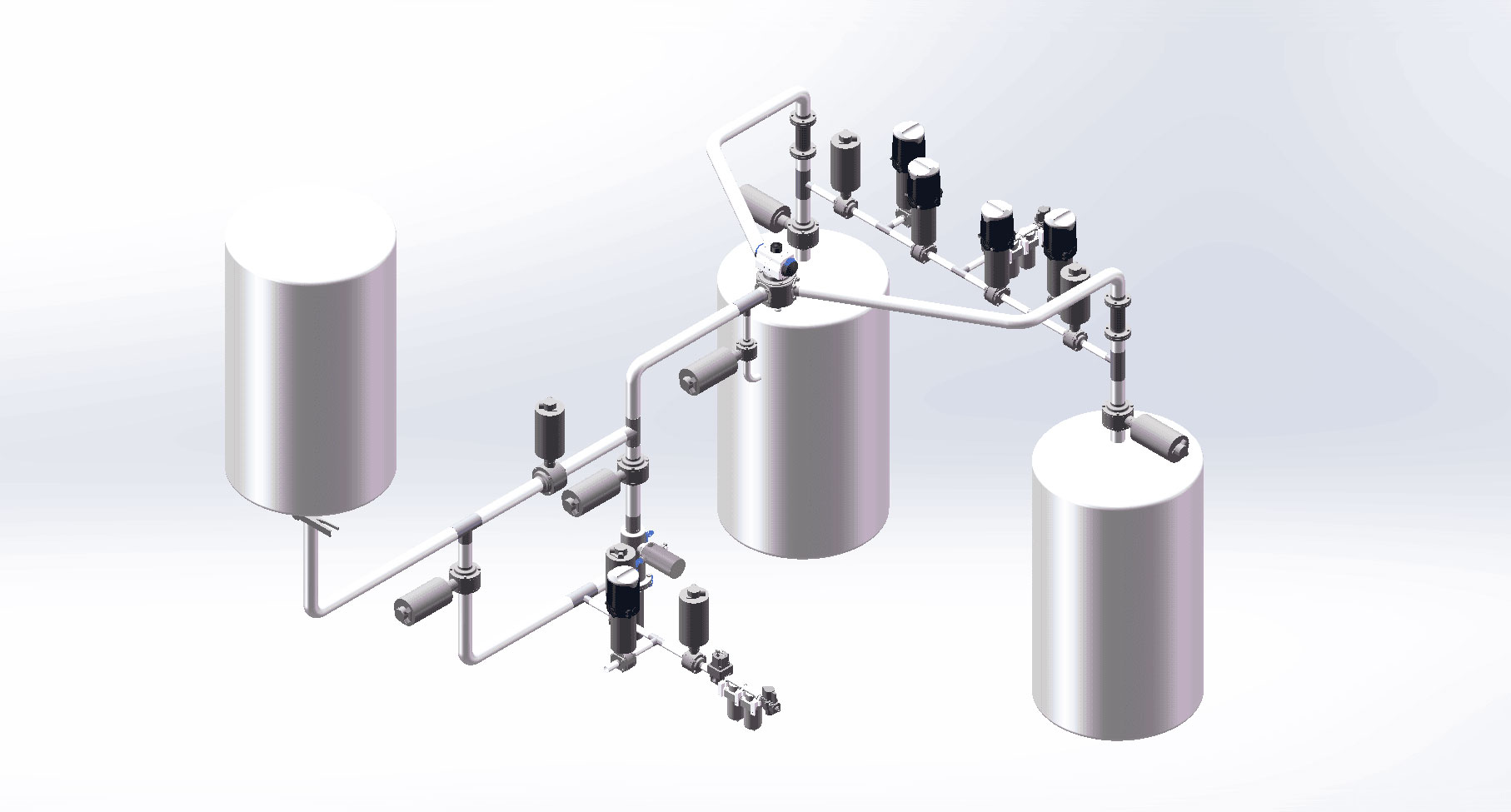

Thorough Pigging Arrangement Engineering and Integration

That detailed pigging system entails a important framework for pipeline overhaul. This mechanism consists of the embedding of dedicated instruments called pigs, which proceed through lines to scrub, examine, and conserve their condition. The structure stresses features such as tubing diameter, ingredient, pig class, and operational needs. A intelligently crafted system delivers potent pigging operations while decreasing downtime and potential injuries. Installation customs need careful management, skilled professionals, and strict adherence to safety measures to enable a protected and successful effect

Industrial Pigging Equipment for Broad Purposes

Manufacturing pigging apparatuses are crucial means employed across a sizable range of industries. These implements advance secure and successful disinfecting, examination, and care of conduits and other tubular edifices. Pigging embraces deploying constructed apparatuses known as pigs through pipes to handle countless tasks. Common types of industrial pigging devices include cleaning pigs, inspection pigs, and delivery pigs. Cleaning pigs are fabricated to eliminate debris, build-up, and impurities from pipelines. Inspection pigs are provided with measuring tools that accumulate information about the health of pipe bases. Transport pigs are operated to convey materials through pipelines. The use of industrial pigging products delivers numerous advantages, such as diminished downtime, improved pipeline strength, and maximized operational capacity. These implements are commonly operated in areas such as oil and gas, water treatment, chemical production, and food manufacturing.Full Examination of Pipeline Pigging

Pipeline pigging is an indispensable technique used within the oil and gas realm to examine pipelines. This crucial assignment comprises inserting designed tools, named pigs, into the pipe. Pigs are created to pass through the range of the pipeline, performing various assignments.

Many sorts of pigs are obtainable, each customized for a particular target. Common uses of pipeline pigging cover checking for defects, cleaning, and surface treatment.

- Benefits of Pipeline Pigging

- Consequences on Operational Efficiency

- Varieties of Pipeline Pigs

Consistent Sanitation using Pigging Setups

Pigging methods contribute a sound answer for upholding sanitation inside pipes. These systems utilize dedicated gadgets that progress through the pipeline sequence, quickly cleaning deposits. The process is especially constructive for categories that need rigorous antisepsis regulations. Pigging technologies supply a cost-saving and expedient approach for cleansing lines, lowering the threat of pollution.

Picking Pigging Devices for Tailored Specifications

Pigging tools performs a key role in successful pipeline operation. When appointing pigging gear, it is mandatory to consider the targeted demands of your assignment. This includes checking elements such as pipeline diameter, flow flux, product type, and restoration demands.

Various pigging forms are provided, each developed for distinct objectives. Such as, some pigs are developed for surveillance, while others are deployed for taking away fouling or separating product parcels.

Additionally, pigging apparatus constituents should be compatible with the moved content.

It is frequently preferred to work alongside a specialist in pigging solutions to ascertain that you opt for the most proper device for your customized wants.

Conduit Maintenance Methods - A Cost-Saving Approach

Pipeline tools offer a broad array of pros for fields utilizing ducts. By competently sterilizing and assessing duct internals, pigging systems boost operational efficiency and reduce maintenance outgoings.

A fundamental strong point of pigging systems is their aptitude to eradicate residue such as dirt, debris, and wear particles. This scheduled sanitation secures unobstructed pipeline discharge and stops costly downtime.

Moreover, pigging systems can be utilized to examine the shape of pipelines, identifying potential complications before they amplify into significant concerns. This strategic plan assists to extend the lifespan of pipelines and cut back overall maintenance expenses.

Upholding Hygiene in Pigging Procedures

Piggy rearing setups are strongly based on appropriate hygiene regulations to reduce the distribution of infections. Enforcing rigorous hygiene protocols assures a healthy setting for pigs, hence contributes to advanced health outcomes and productivity.

Thorough cleaning and disinfection of buildings is mandatory to block the spread of harmful pathogens. Efficient residues management likewise plays a significant part in supporting hygiene.

What's sanitary pigging systems more, {workers